What is a Vapor Chamber

If you’ve ever wondered what is a vapor chamber and how it plays a role in cooling modern electronics, you’re in the right place. A vapor chamber is an advanced thermal management device designed to efficiently spread heat across a surface, keeping high-performance components cool and running smoothly. In this article, we’ll explain what a vapor chamber is, how it works, and why it’s becoming increasingly important in the world of electronics cooling.

What is a Vapor Chamber?

A vapor chamber is a flat type of heat pipe. It spreads heat evenly over a surface by using the evaporation and condensation of liquid inside a sealed, flat metal chamber.

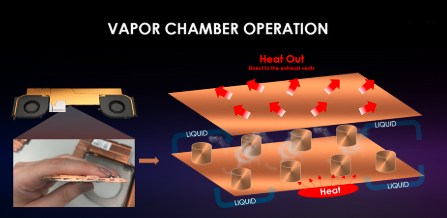

How Does a Vapor Chamber Work?

- Heat and Evaporation

Vapor chambers use heat to evaporate a liquid inside, turning it into vapor that carries heat away. When the vapor cools, it turns back into liquid, releasing the heat and continuing the cycle.

- Vapor Spreading

The vapor quickly spreads out inside the flat chamber, moving to cooler areas. This spreads the heat evenly across the chamber.

- Condensation and Heat Release

When the vapor reaches cooler spots, it turns back into liquid, releasing the heat it carried. This heat is then taken away by a heat sink or the device’s body.

- Liquid Return via Wick

The liquid flows back to the hot area through tiny channels in the wick by capillary action (like how a paper towel pulls up water), ready to start the cycle again.

Important Parts

- Wick: A fine porous material inside the chamber that holds and moves the liquid back to the heat source. It works in any position, even upside down.

- Working Fluid: Most heat pipes use de-ionized water because it absorbs heat easily and is safe. Sometimes, other fluids are used if different temperatures are needed.

Heat causes fluid to evaporate → vapor spreads heat → vapor condenses and releases heat → liquid returns via wick → cycle repeats continuously, keeping devices cool efficiently and quietly.

Why Vapor Chambers Are Great for Cooling Electronics

- Even Heat Spread

They spread heat evenly across their surface, preventing hot spots and keeping electronics running smoothly.

- Fast Heat Transfer

Vapor chambers rapidly transfer heat by converting liquid to vapor and back, efficiently moving heat from hot areas to cooler ones to keep devices cool under heavy loads.

- Thin and Light

Vapor chambers are thin and lightweight, making them easy to fit into tight spaces and helping keep devices portable without sacrificing cooling performance.

- Reliable and Quiet

Vapor chambers have no moving parts, which makes them long-lasting and completely silent during operation.

- Works for Many Devices

Vapor chambers can efficiently cool a variety of devices, including smartphones, laptops, and high-performance computers.

Vapor chambers are effective, dependable, and small cooling parts that work great in today’s powerful electronic devices.

Vapor Chamber vs. Heat Pipe

Vapor chambers and heat pipes cool devices without using power or moving parts. They move heat by evaporating and condensing a special fluid sealed inside. However, they have different designs, distribute heat differently, and are suited for different applications.

- Structure

- Heat Pipes: Heat Pipes are long, thin tubes that can be bent to fit into tight spaces. Inside, a special fluid turns into vapor when heated at one end, moves to the cooler end where it turns back into liquid, and carries heat along the pipe this way.

- Vapor Chambers: These are flat, thin plates that spread heat across their entire surface area. The working fluid evaporates and condenses inside the flat chamber, allowing heat to spread out evenly over a larger area.

- Heat Spreading

- Heat Pipes: Transfer heat mainly in one direction—from the hot spot to the cooler end along the pipe. This makes them ideal for moving heat from one point to another.

- Vapor Chambers: They spread heat evenly in two dimensions across a flat surface, making them ideal for cooling large, flat components like CPUs or GPUs where consistent heat distribution is essential.

- Orientation Sensitivity

- Heat Pipes: Their performance depends on orientation, as gravity influences how the fluid returns to the heat source. They work best when positioned vertically and may be less effective when horizontal or upside-down.

- Vapor Chambers: Work effectively regardless of orientation since the fluid moves freely inside the flat chamber without relying on gravity.

- Thickness

- Heat Pipes: Generally thicker and bulkier due to their tube shape, which can limit their use in very tight spaces.

- Vapor Chambers: Much thinner and flatter, making them ideal for compact devices like thin laptops or smartphones, where space is limited.

- Cost

- Heat Pipes: Are typically less expensive to produce because their design is simpler and well-established.

- Vapor Chambers: Typically more expensive because of their intricate flat design and the complexity of the manufacturing process.

- Applications

- Heat Pipes: Ideal for transferring heat over longer distances or targeting specific hotspots, such as moving heat from a CPU to a heatsink positioned elsewhere in the device.

- Vapor Chambers: They distribute heat evenly across flat surfaces, making them ideal for high-performance, compact devices like gaming laptops and smartphones that require reliable cooling.

Heat pipes transfer heat over long distances but need proper positioning, while vapor chambers evenly spread heat and work reliably in any position, ideal for modern devices.

Future Trends and Innovations

Future cooling technology is focused on improving vapor chambers and heat pipes to meet the needs of modern devices. As gadgets get smaller but more powerful, old cooling methods can’t keep up. Here are some important new ideas:

- Nanomaterials and Microstructures: Using materials like carbon nanotubes and advanced mesh designs to boost heat transfer and temperature control.

- Hybrid Cooling Systems: Combining vapor chambers with liquid cooling to handle higher heat loads in powerful electronics.

- 3D Printing Customization: Creating custom cooling parts with 3D printing that fit into tight or complex spaces, especially for specialized uses like aerospace.

- Ultra-Thin Vapor Chambers: Very slim cooling plates designed to fit into compact devices without losing cooling power.

- Expanded Applications: Using vapor chambers and heat pipes in new areas beyond electronics, like cooling batteries in electric and hybrid vehicles.

These innovations aim to enhance efficiency, adaptability, and integration, supporting the growing demand for reliable thermal solutions in various industries.