Acoustic Barriers: Enhancing Sound Insulation Across Industries

Acoustic barriers are essential products designed to reduce airborne noises and minimize impact sounds in various applications. These sound-insulating solutions prevent sound transmission loss, making them invaluable in environments where noise reduction is critical. The ability of acoustic barriers to provide excellent vibration-dampening performance further enhances their effectiveness in controlling sound. From automotive to construction, the versatility of acoustic barriers makes them suitable for multiple industries and settings. This article explores the different types of acoustic barriers, their applications, benefits, and how they contribute to creating quieter and more comfortable environments.

Understanding Acoustic Barriers

Acoustic barriers are designed to insulate sound effectively, and they come in various forms tailored to meet specific needs. The barriers can be supplied in sheets, die-cut, or water jet-cut to fit any requirement, providing flexibility for installation. Additionally, they are particularly suited for applications requiring excellent malleability, allowing them to adapt to slightly curved and wavy surfaces.

Key Features of Acoustic Barriers

- Sound Insulation: Acoustic barriers are primarily engineered to reduce sound transmission. They are particularly effective in preventing both airborne and impact sounds, contributing to a quieter environment.

- Vibration Dampening: These barriers also serve as anti-vibration pads, reducing impact sounds, which is especially beneficial in industrial settings where machinery operation is prevalent.

- Thermal Radiation Reflection: Many acoustic barriers are designed to reflect thermal radiation while providing sound insulation, making them effective in high-temperature environments.

- Customizable Options: Acoustic barriers can be tailored to fit various specifications and applications, ensuring optimal performance in diverse scenarios.

Types of Acoustic Barriers

1. Polymeric Acoustic Barriers

Polymeric acoustic barriers, such as C03 (1.4mm) and C09 (2.5mm), are low-density vinyl membranes loaded with naturally occurring materials. These barriers are free from harmful substances, including lead and unrefined aromatic oils, making them safe for use in various applications. They are specifically designed to enhance the sound insulation of existing panels made of metal, wood, or plastic. These barriers effectively overcome coincidence dip resonance in lightweight composites, such as plywood and hollow core panels.

2. Bitumen PE Foil Covered Acoustic Barriers

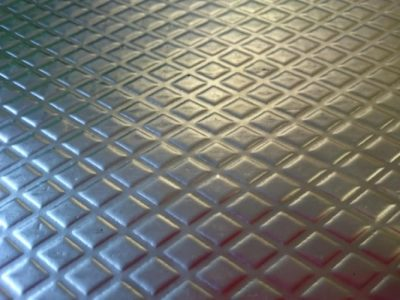

Products like C022 (3mm) and C023 (5mm) feature diamond-embossed black PE faced barriers with a self-adhesive backing. These barriers excel at achieving flat sound insulation and preventing transmission loss, providing a neat and tidy solution for soundproofing. The PE foil surface prevents seepage from the oil in the bitumen-based barrier, ensuring cleanliness while enhancing bonding capabilities with substrates.

3. Bitumen Aluminium Acoustic Barriers

The C024 barrier consists of a dense layer of bitumen, polymers, and mineral fillers, protected by an aluminium foil surface. This design is ideal for applications exposed to heat, such as in automotive and construction vehicles. The barrier dampens sound effectively in engine blocks, ensuring quieter operation in various machinery.

Applications of Acoustic Barriers

Acoustic barriers find extensive application across numerous sectors, each benefiting from their sound-insulating properties. Here are some key areas where acoustic barriers play a critical role:

1. Automotive Industry

In the automotive sector, acoustic barriers are utilized to reduce noise from engine compartments, passenger cabins, and other areas. By insulating sound, these barriers enhance passenger comfort and contribute to a more enjoyable driving experience. Additionally, they assist in minimizing vibrations, ensuring smoother operation of vehicles.

2. Construction and Building

In construction, acoustic barriers are essential for soundproofing walls, ceilings, and floors in residential and commercial buildings. They help to create quieter living and working environments by reducing noise pollution from outside and minimizing sound transmission between rooms.

3. White Goods and Home Appliances

Many household appliances, such as refrigerators and washing machines, utilize acoustic barriers to minimize operational noise. These barriers ensure that appliances run quietly, enhancing user comfort in domestic environments.

4. Marine Applications

In the marine industry, acoustic barriers are vital for reducing noise from engines and machinery on boats and ships. The barriers help create a more pleasant experience for passengers and crew members by minimizing disruptive sounds.

5. Industrial Machinery

For various industrial machines, including earth-moving and agricultural vehicles, acoustic barriers provide sound insulation that protects workers from excessive noise exposure. This application is crucial for maintaining a safe and healthy working environment.

Benefits of Acoustic Barriers

The implementation of acoustic barriers brings numerous advantages, making them a valuable investment for various applications. Here are some key benefits:

1. Enhanced Comfort

By effectively reducing noise levels, acoustic barriers significantly enhance comfort in both residential and commercial spaces. Quieter environments lead to increased productivity, better sleep quality, and overall improved well-being.

2. Improved Safety

In workplaces, especially in industrial settings, acoustic barriers contribute to safety by minimizing noise-related distractions. This improvement allows workers to concentrate on tasks without the interference of excessive noise.

3. Versatility in Applications

The adaptability of acoustic barriers allows them to be utilized in various industries, making them suitable for a wide range of applications. Whether it’s for soundproofing in construction or reducing noise in automotive settings, acoustic barriers offer versatile solutions.

4. Cost-Effective Solution

Implementing acoustic barriers can lead to long-term savings by reducing the need for additional soundproofing measures and minimizing noise-related issues. This cost-effectiveness makes them an attractive choice for businesses and homeowners alike.

5. Eco-Friendly Options

Many acoustic barriers are manufactured using environmentally friendly materials and processes, contributing to sustainability efforts. Choosing eco-friendly options helps reduce the overall environmental impact of sound insulation solutions.

Read Also: Revitalize Your Home: Expert Property Refurbishment Services in London

Quality Control in Acoustic Barriers

To ensure that acoustic barriers meet the highest industry standards, rigorous quality control measures are essential. These measures include testing for sound transmission loss, vibration dampening capabilities, and overall durability. Adhering to strict quality control standards guarantees that clients receive reliable and effective acoustic solutions for their specific needs.

Collaboration for Effective Solutions

At Acoustafoam, collaboration with clients is paramount in achieving optimal results. By understanding the unique challenges faced in various industries, Acoustafoam can provide tailored solutions that go beyond simple sound insulation. Whether addressing sound issues in construction vehicles or improving acoustic environments in marine applications, our team is committed to delivering effective acoustic barrier products that meet the highest standards of quality and performance.

Conclusion: The Future of Acoustic Barriers

Acoustic barriers play a crucial role in enhancing sound insulation across multiple sectors. As technology advances and the demand for quieter environments increases, the importance of acoustic barriers will only grow. These products offer tailored solutions that address diverse challenges, providing comfort, safety, and versatility.